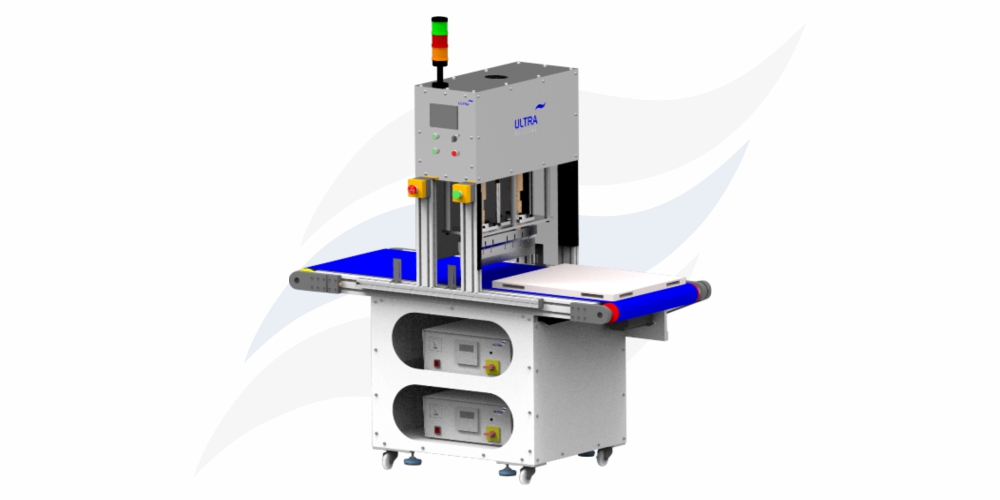

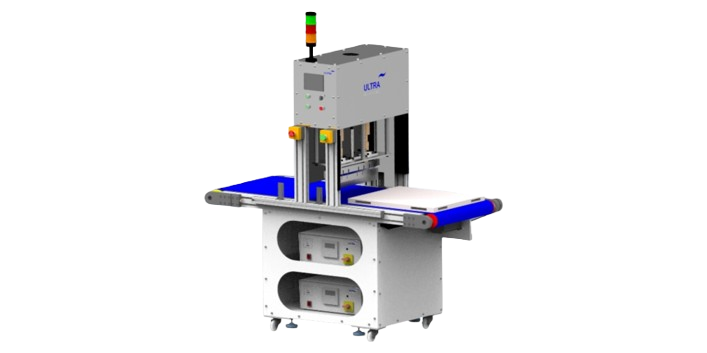

Multi-functional Food Ultrasonic Cutting Machine

1500000.0 INR/Number

Product Details:

- Material Food-grade Stainless Steel

- Dimension (L*W*H) 1800mm x 800mm x 1500mm Millimeter (mm)

- Power 2500W Watt (w)

- Voltage 220V / 380V Volt (v)

- Frequency 20-40 kHz Kilohertz ( KHZ )

- Temperature Ambient to 50C Celsius (oC)

- Click to View more

X

Multi-functional Food Ultrasonic Cutting Machine Price And Quantity

- 1 Number

- 1500000.0 INR/Number

Multi-functional Food Ultrasonic Cutting Machine Product Specifications

- 2500W Watt (w)

- Ambient to 50C Celsius (oC)

- 220V / 380V Volt (v)

- 1800mm x 800mm x 1500mm Millimeter (mm)

- Food-grade Stainless Steel

- 20-40 kHz Kilohertz ( KHZ )

Product Description

The multifunctional ultrasonic food slicing machine, equipped with advanced ultrasonic cutting technology, is designed to slice sticky, frozen, delicate, and challenging products with ease. It delivers precise cuts for sponge cakes, cheesecakes, brownies, pies, quiches, pizzas, pastries, flapjacks, and many other products.The machine can slice two round products simultaneously and also handle half-sheet products directly from the pan. It operates in a semi-automatic mode.Advanced Ultrasonic Cutting Technology

Utilizing a state-of-the-art ultrasonic titanium alloy blade, this machine ensures clean, consistent cuts without crushing or deforming delicate products. The ultrasonic vibrational motion significantly reduces product adhesion to the blade, resulting in minimal waste and high-quality finished slices.

User-Friendly Operation and Versatile Applications

The intuitive PLC touch screen interface allows effortless adjustment of cutting parameters, accommodating different food types and desired thickness. Designed for both automatic and semi-automatic operation, it is suitable for bakeries, cheese factories, confectioners, and frozen food producers alike.

Safety and Hygiene Built In

Safety remains paramount with features like an emergency stop switch and an automatic fault self-diagnostic system. The self-cleaning ultrasonic mechanism ensures that hygiene standards are maintained, reducing downtime and manual intervention during production.

FAQs of Multi-functional Food Ultrasonic Cutting Machine:

Q: How does the ultrasonic cutting machine maintain consistent slice thickness?

A: The machines advanced PLC touch screen system enables precise selection and adjustment of the cutting thickness, ranging from 1mm to 150mm. The ultrasonic blade ensures uniform slices regardless of the selected thickness, delivering consistent results every time.Q: What is the process for cleaning the blades and maintaining hygiene?

A: The machine includes a self-cleaning ultrasonic system that utilizes sonic vibrations to remove residue from the titanium alloy blade. This feature ensures optimal hygiene and reduces manual cleaning requirements, supporting compliance with food safety standards.Q: When should I choose automatic versus semi-automatic operation?

A: Automatic mode is ideal for continuous, high-volume production lines where minimal user intervention is desired. Semi-automatic mode provides greater control for specialized products or smaller batches that might require closer monitoring or manual adjustments.Q: Where can this ultrasonic cutting machine be installed and used?

A: Thanks to its adaptable design and food-grade stainless steel construction, the machine can be deployed in bakeries, cheese factories, frozen food processing plants, confectionery units, and other industrial food manufacturing environments across India.Q: What types of foods can be processed with this machine?

A: This machine is designed for a range of products including cakes, cheese, bread, frozen foods, and various confectionery items. Its adjustable cutting parameters and robust blade can handle both soft and dense food products.Q: How does using this ultrasonic machine benefit my food processing business?

A: The ultrasonic cutting machine offers precise slicing, minimal product deformation, and rapid throughputup to 70 cuts per minute. Enhanced hygiene features and automated functions reduce labor costs, while consistent quality and reduced waste maximize business efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free