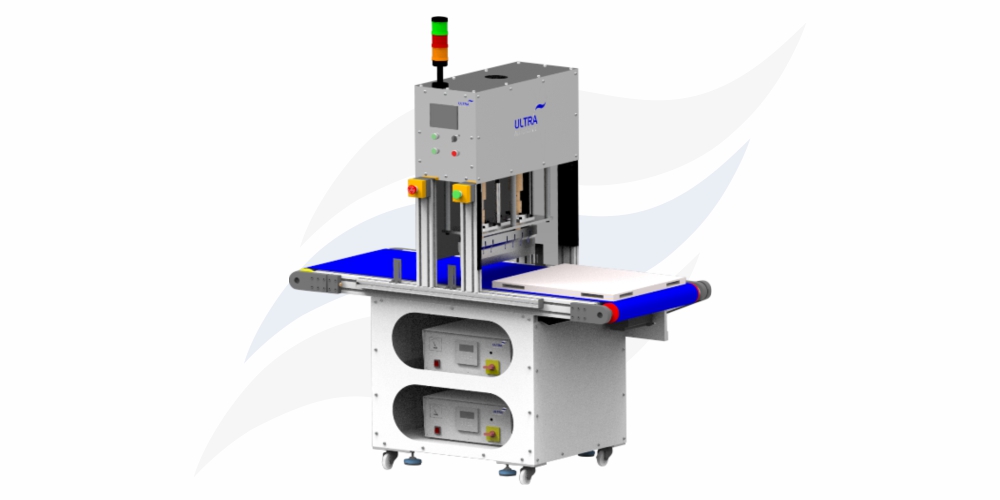

ULTRASONIC FOOD CUTING MACHINE

Product Details:

- Usage cream multilayer cake, sandwich mousse cake, date cake, steamed sandwich cake, Napoleon, Swiss roll, brownie, tiramisu, cheese, ham sandwich, It can cut baked and frozen foods of various shapes, such as square, triangle.

- Size Approx. (483 X 458 X 238) mm

- Height 238 Millimeter (mm)

- Dimension (L*W*H) Approx. (483 X 458 X 238) mm Millimeter (mm)

- Product Type Ultrasonic Food Cutting Machine

- Weight 22 Kilograms (kg)

- Color Not Specified

- Click to View more

ULTRASONIC FOOD CUTING MACHINE Price And Quantity

- 700000 INR/Piece

- 1 Piece

ULTRASONIC FOOD CUTING MACHINE Product Specifications

- cream multilayer cake, sandwich mousse cake, date cake, steamed sandwich cake, Napoleon, Swiss roll, brownie, tiramisu, cheese, ham sandwich, It can cut baked and frozen foods of various shapes, such as square, triangle.

- Approx. (483 X 458 X 238) mm Millimeter (mm)

- 22 Kilograms (kg)

- Ultrasonic Food Cutting Machine

- 20 & 40 Kilohertz ( KHZ )

- 238 Millimeter (mm)

- 483 Millimeter (mm)

- Approx. (483 X 458 X 238) mm

- 458 Millimeter (mm)

- Not Specified

ULTRASONIC FOOD CUTING MACHINE Trade Information

- 2 Piece Per Week

- 2 Week

- No

- Corrugated Box

- Maharashtra

- UQSR Certified MQA Certified Udyam Certified Our all products are CE and RoHS certified

Product Description

ULTRAAUTOSONIC provides an innovative ultrasonic food-cutting technology: it ensures productivity gains and the optimal quality of food slicing. Ultrasonic cutting is particularly suitable for soft, frozen, or fresh food products such as cheeses, meats, cold meats, pastries, etc. It is also suitable for all shapes and sizes: plates, pieces, strips, layers, rounds, blocks, bread, and more. Ultrasonic mechanical vibrations have a frequency above the hearing range of the human ear. These pressure waves are produced by a generator.

In an acoustic assembly, the generator converts the electrical frequency of the network into high-frequency electrical energy. The booster, or amplitude amplifier, is used to increase or reduce the amplitude produced by the converter. It transmits the energy to the last element of the acoustic chain: the horn. The horn, a titanium-slicing blade, vibrates at high frequency. These vibrations create perfect slicing.

Effortless Precision Cutting

Utilizing ultrasonic technology, the machine offers effortless and precise food slicing without compromising the quality, even for delicate items like mousse cakes or sticky brownies. The titanium horn ensures longevity and optimal performance, while adjustable power settings allow a tailored approach for different products.

Versatile Applications

Whether you are slicing cream-filled cakes, cheese, or even frozen foods in various shapes, this machine delivers consistent results. Its capability to handle both baked and frozen goods makes it a reliable tool for bakeries, catering services, and food production facilities.

Designed for Professional Needs

With robust construction and compact dimensions, the Ultrasonic Food Cutting Machine is engineered for commercial environments. Its cleanliness, reduced waste, and adaptability meet the demands of quality-focused manufacturers, service providers, and suppliers across India.

FAQs of ULTRASONIC FOOD CUTING MACHINE:

Q: How does the ultrasonic food cutting machine benefit bakery operations?

A: By using high-frequency ultrasonic vibrations, the machine produces clean and smooth cuts, reducing product waste and maintaining the original appearance of delicate confections and sandwiches. This process also minimizes sticking and smearing, enhancing both presentation and shelf life.Q: What food items can be processed using this cutting machine?

A: The machine is suitable for a wide spectrum of items, including cream multilayer cakes, mousse cakes, date cakes, Swiss rolls, brownies, tiramisu, cheese, and sandwiches. It efficiently slices both baked and frozen goods in various shapes such as squares and triangles.Q: When should you choose the different power settings (1000/1200/1500/1800/2000 & 500 Watt)?

A: Selecting the appropriate power setting depends on the density and moisture content of the food being cut. Higher power (e.g., 2000W) is optimal for dense or frozen products, while lower power works well for softer or delicate items, ensuring precision without damage.Q: Where is the ultrasonic food cutting machine typically used?

A: This machine is widely employed in commercial bakeries, food processing plants, catering businesses, and large-scale kitchens throughout India. Its versatile design makes it suitable for any professional food preparation setting seeking high-quality, consistent slicing.Q: What is the process for cleaning and maintaining this machine?

A: Routine maintenance involves cleaning the titanium horn and surrounding parts after each operation to prevent residue buildup. Most components are designed for easy removal and washing, supporting hygiene standards in food service environments.Q: How does the ultrasonic technology improve cutting results compared to conventional methods?

A: Ultrasonic cutting utilizes rapid vibrations to create a frictionless surface, which greatly reduces pressure on the product. This results in cleaner cuts, minimized crumbling or deformation, and less manual effort compared to traditional blades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS