Ultrasonic Booster

Product Details:

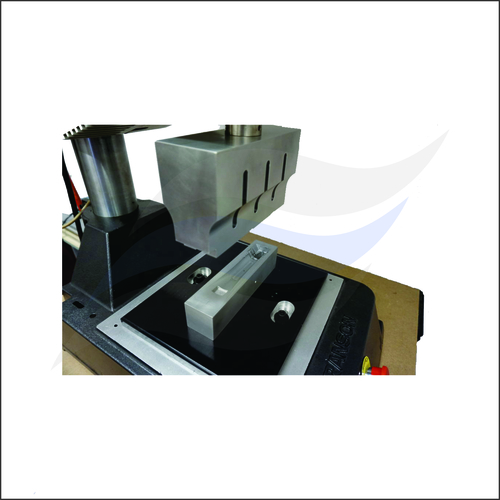

- Product Type Ultrasonic Booster

- Material High-grade Titanium Alloy or Stainless Steel

- Function Amplifies ultrasonic vibrations for varied industrial applications

- Application Plastic welding, ultrasonic cleaning, packaging, textile, automation, and other ultrasonic machinery

- Size Customizabletypical ranges from 15 mm to 80 mm diameter

- Weight Standard: 0.5 kg to 2.5 kg dependent on design & material

- Capacity Designed to handle input frequencies from 15 kHz to 40 kHz

- Click to View more

Ultrasonic Booster Price And Quantity

- 20000.0 INR/Number

- 1 Number

Ultrasonic Booster Product Specifications

- Standard: 0.5 kg to 2.5 kg dependent on design & material

- High-grade Titanium Alloy or Stainless Steel

- Amplifies ultrasonic vibrations for varied industrial applications

- Plastic welding, ultrasonic cleaning, packaging, textile, automation, and other ultrasonic machinery

- Customizabletypical ranges from 15 mm to 80 mm diameter

- Designed to handle input frequencies from 15 kHz to 40 kHz

- High amplification ratio, precision machining, easy integration, anti-resonance design

- High durability, maximum vibration transmission, corrosion resistant, long service life

- Ultrasonic Booster

Ultrasonic Booster Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 50 Number Per Day

- 1 Days

- Yes

- Wooden Box

- All India

- UQSR Certified MQA Certified Udyam Certified Our all products are CE and RoHS certified

Product Description

An ultrasonic booster is a device that is used to amplify the amplitude or power of ultrasonic waves. Ultrasonic waves are sound waves that have a frequency above the range of human hearing, typically in the range of 20 kHz to several megahertz.

Ultrasonic boosters are typically used in ultrasonic cleaning and welding applications where the ultrasonic waves are used to break up and remove dirt and contaminants or to fuse two materials together. In these applications, the ultrasonic booster is placed between the ultrasonic transducer, which generates the ultrasonic waves, and the workpiece. The booster amplifies the ultrasonic waves, allowing for more efficient cleaning or welding.

Ultrasonic boosters can be designed in a variety of shapes and sizes, depending on the specific application. They are often made of materials such as titanium or aluminum, which have high acoustic transmission properties, and are designed to be resonance-matched to the frequency of the ultrasonic transducer.

Exceptional Frequency Compatibility

Choose from standard frequencies including 15 kHz, 20 kHz, 28 kHz, 35 kHz, and 40 kHz, or opt for customization to suit your specific process requirements. This flexibility ensures optimal resonance and performance in diverse ultrasonic applications across industrial sectors.

Superior Material & Surface Protection

Each booster is CNC-machined for unwavering dimensional accuracy from premium titanium alloy or stainless steel. Hard anodizing or polished finishes deliver enhanced corrosion resistance, safeguarding against chemical exposures and extending operational longevity in demanding environments.

Flexible Mounting and Integration

Installation is simplified with threaded or flange mounting options. The booster is designed to fit standard converters and horns, making it highly adaptable for both OEM equipment and aftermarket upgrades, reducing downtime during integration.

FAQ's of Ultrasonic Booster:

Q: How does the Ultrasonic Booster enhance industrial ultrasonic applications?

A: The Ultrasonic Booster amplifies the vibration energy transferred from ultrasonic converters to horns, improving process efficiency in plastic welding, cleaning, packaging, textile production, and automation by delivering higher amplitude and precise control.Q: What customization options are available for frequency and amplification ratio?

A: Customers can select standard frequencies from 15 kHz to 40 kHz, along with amplification ratios like 2:1, 2.5:1, or 3:1. Custom frequencies and ratios are also available to match unique application requirements.Q: Where can the Ultrasonic Booster be used?

A: It is suitable for varied industrial environments, including manufacturing plants, assembly lines, ultrasonic cleaning facilities, packaging stations, and textile factories, thanks to its robust corrosion resistance and compatibility with OEM and aftermarket machinery.Q: What process does the booster undergo for surface protection?

A: Each booster receives either hard anodizing or polishing, ensuring superb surface protection that resists corrosion and chemical exposure, crucial for maintaining high performance and durability over time.Q: When is it recommended to choose custom sizes and amplification ratios?

A: Custom sizes and ratios should be selected when standard options do not meet the specific demands of your process or equipment, ensuring maximum efficiency and compatibility with specialized ultrasonic systems.Q: What are the benefits of CNC machining in the manufacturing of Ultrasonic Boosters?

A: CNC machining achieves superior dimensional accuracy and balance in each booster, leading to consistent vibration amplification, easy equipment integration, and long operational service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free