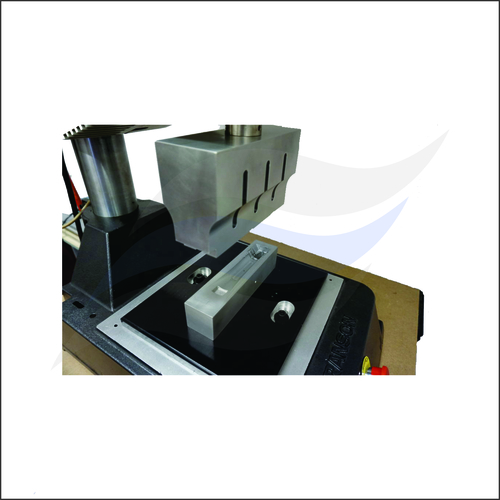

Ultrasonic Horn

Product Details:

- Product Type Ultrasonic Horn

- Material Titanium Alloy

- Function Transmits ultrasonic vibrations for cutting, welding, or emulsifying applications

- Application Plastic welding, ultrasonic cutting, medical devices, packaging, and sonochemistry

- Size Customizable; standard sizes available (e.g., 20 kHz, 35 kHz, 40 kHz)

- Weight Variable depending on size; typical range 0.5 - 2.5 kg

- Capacity Handles high-frequency vibration energy up to 3000 W

- Click to View more

Ultrasonic Horn Price And Quantity

- 01 Number

- 32000 INR/Number

Ultrasonic Horn Product Specifications

- Handles high-frequency vibration energy up to 3000 W

- Corrosion-resistant, easy to install, robust structure, compatible with multiple ultrasonic devices

- Ultrasonic Horn

- Plastic welding, ultrasonic cutting, medical devices, packaging, and sonochemistry

- Variable depending on size; typical range 0.5 - 2.5 kg

- Titanium Alloy

- High durability, efficient ultrasonic energy transmission, and precise performance

- Transmits ultrasonic vibrations for cutting, welding, or emulsifying applications

- Customizable; standard sizes available (e.g., 20 kHz, 35 kHz, 40 kHz)

Ultrasonic Horn Trade Information

- 100 Number Per Week

- 2 Days

- Yes

- Wooden Box

- Australia, Middle East, Eastern Europe, Western Europe, Africa, Central America, North America, South America, Asia

- All India

- UQSR Certification MQA Certification Udyam Registration

Product Description

A Ultrasonic Horn is a device that amplifies and transmits high-frequency sound waves, typically between 15 and 100 kHz, generated by an ultrasonic transducer. The horn is designed to efficiently transfer the vibrational energy from the transducer to the material being processed, such as welding, cutting, cleaning, or bonding.

The ultrasonic horn is usually made of a metal alloy, such as titanium or aluminium, which has high acoustic conductivity and low damping. The shape of the horn is carefully designed to match the acoustic properties of the transducer and the material being processed. The horn may have different configurations, including a booster horn, a sonotrode, or a horn stack.

Ultrasonic horns are widely used in various industries, such as automotive, aerospace, medical, food, and electronics. They offer several advantages over traditional mechanical or thermal processing methods, including high precision, low energy consumption, and non-contact processing.

Versatile Industrial Applications

Designed for plastic welding, ultrasonic cutting, medical devices, packaging, and sonochemistry, the Ultrasonic Horn delivers reliable ultrasonic energy across various sectors. The durable titanium alloy construction and high energy efficiency cater to both standard and custom requirements, enhancing productivity and ensuring long-term operation even under intensive usage.

Customizable Design and Compatibility

Our Ultrasonic Horns provide extensive customization in shape, frequency, and dimensions, tailored to unique process specifications. They seamlessly integrate with major ultrasonic systems, including Branson, Dukane, and Rinco, guaranteeing both installation flexibility and operational precision. Standard and bespoke sizing allows for easy adaptation across different ultrasonic setups.

FAQ's of Ultrasonic Horn:

Q: How does the Ultrasonic Horn achieve high acoustic efficiency in my application?

A: The Ultrasonic Horn features low impedance and precision construction using titanium alloy, enabling over 95% energy transfer. Its robust design and accurate dimensions minimize energy loss, delivering reliable performance in welding, cutting, or emulsifying operations.Q: What customization options are available for this Ultrasonic Horn?

A: You can customize the horn's shape, frequency (15 kHz to 60 kHz), and dimensions. This ensures optimal compatibility and performance for specific tasks, such as different plastic welding techniques, medical procedures, or specialized cutting operations.Q: When is minimal maintenance required for the Ultrasonic Horn?

A: Thanks to its corrosion-resistant titanium alloy and high durability (HRC 34-36), the horn requires minimal maintenance during typical operating cycles. Routine visual inspections ensure sustained performance and safety in continuous industrial use.Q: Where can the Ultrasonic Horn be installed?

A: Suitable for integration with Branson, Dukane, Rinco, and other leading ultrasonic systems, the horn installs via threaded or flange connections. This allows for flexibility in a wide array of production environments, from medical device manufacturing to packaging plants.Q: What is the typical usage process for the Ultrasonic Horn?

A: After installation on an ultrasonic system, the horn transmits high-frequency vibrations to the target material or product. Its precise tolerance (0.01 mm) and robust build ensure consistent operation during plastic welding, cutting, or sonochemical processing.Q: What benefits does the Ultrasonic Horn offer to manufacturers and service providers?

A: Manufacturers and service providers benefit from high durability, efficient energy transmission, and versatile compatibility. The horn enables precise, reliable ultrasonic processing, reduces downtime, and supports a wide range of applications, boosting operational quality and throughput.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free