Ultrasonic Transducer

Product Details:

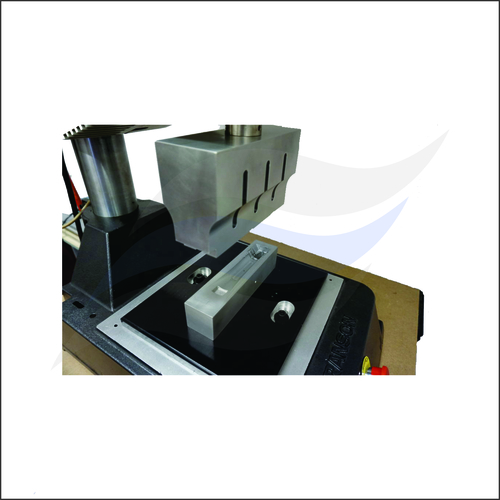

- Product Type Ultrasonic Transducer

- Material Stainless Steel and Piezoelectric Ceramic

- Function Generates and transmits high-frequency ultrasonic waves

- Application Ultrasonic cleaning, medical devices, welding, sensing, flow measurement

- Size Standard size, custom sizes available

- Weight Approx. 450 grams

- Capacity Frequency capacity up to 40 kHz

- Click to View more

Ultrasonic Transducer Price And Quantity

- 01 Number

- 40000 INR/Number

Ultrasonic Transducer Product Specifications

- Ultrasonic cleaning, medical devices, welding, sensing, flow measurement

- Standard size, custom sizes available

- Approx. 450 grams

- Frequency capacity up to 40 kHz

- Corrosion resistant, high accuracy, long operational life

- High sensitivity, durable, energy efficient, stable performance

- Generates and transmits high-frequency ultrasonic waves

- Stainless Steel and Piezoelectric Ceramic

- Ultrasonic Transducer

Ultrasonic Transducer Trade Information

- Cash Advance (CA), Telegraphic Transfer (T/T), Cheque, Cash in Advance (CID)

- 20 Number Per Week

- 20 Week

- Yes

- Wooden Box

- Middle East, Western Europe, Australia, Africa, Central America, North America, Eastern Europe, South America, Asia

- All India

- USQR Certified MQA Certified Udyam Certified

Product Description

Ultrasonic Transducers are devices that convert electrical energy into high-frequency mechanical vibrations (ultrasonic waves) and vice versa. These devices are widely used in various applications, such as medical imaging, cleaning, material testing, and distance measurement.

The basic design of an ultrasonic transducer consists of a piezoelectric element sandwiched between two electrodes. When a voltage is applied to the electrodes, the piezoelectric element contracts and expands rapidly, producing ultrasonic waves. Conversely, when ultrasonic waves are incident on the transducer, they cause the piezoelectric element to vibrate, generating an electrical signal. The frequency of the ultrasonic waves produced or detected by the transducer depends on the thickness of the piezoelectric element and the applied voltage.

Ultrasonic transducers are available in various configurations, including single-element and array transducers. Single-element transducers are simpler and less expensive, but they have limited directional sensitivity and may require mechanical scanning to obtain images. Array transducers, on the other hand, consist of multiple elements arranged in a specific pattern, allowing for electronic steering and focusing of the ultrasonic beam. This makes them more versatile and suited for applications such as medical imaging and non-destructive testing.

Durable Build for Demanding Applications

With a corrosion-resistant casing made from stainless steel and advanced piezoelectric ceramics, this ultrasonic transducer delivers reliable performance even in challenging industrial environments. Its IP54 protection ensures safe operation in dusty and wet areas, making it suitable for cleaning, sensing, and welding processes.

Optimized Efficiency and Sensitivity

Engineered to operate at frequencies up to 40 kHz, this transducer offers high sensitivity and stable performance for precision-driven tasks. The device's energy efficiency and long operational life help reduce cost and maintenance needs, supporting consistent usage in both industrial and medical applications.

FAQ's of Ultrasonic Transducer:

Q: How should the ultrasonic transducer be installed for best performance?

A: The transducer should be mounted using the screw type or bolt mount method to ensure stability and optimal transmission. Ensure the 2-pin cable connection is secure, and the device is fitted according to standard or custom size requirements in environments within the operating temperature range of 0C to 80C.Q: What are the primary applications for this ultrasonic transducer?

A: This transducer is widely used in ultrasonic cleaning systems, medical devices, welding machinery, flow measurement, and sensing equipment. Its high sensitivity and energy-efficient design make it suitable for precise and durable operations in these fields.Q: When is it recommended to use models with higher output power?

A: Models with output power closer to 1000W are ideal when dealing with larger volumes, intensive cleaning tasks, or industrial processes requiring higher ultrasonic energy. For smaller or sensitive applications, lower power settings may be preferable.Q: Where can I purchase or request custom sizes for this transducer in India?

A: The product is available directly from manufacturers, suppliers, and service providers across India. You can request standard or custom sizes by contacting the listed supplier or manufacturer for project-specific requirements.Q: What process does this transducer use to generate ultrasonic waves?

A: Utilizing piezoelectric ceramics, the transducer converts electrical energy from AC 220V/110V inputs into mechanical vibrations, generating ultrasound frequencies between 28 kHz and 40 kHz. These vibrations are efficiently transmitted via its corrosion-resistant stainless steel construction.Q: How long does the ultrasonic transducer typically last in continuous operation?

A: The transducer is engineered to deliver a lifespan exceeding 10,000 operational hours, with stable performance and minimal maintenance required. Its robust materials and protective IP54 rating contribute to its extended durability during long-term use.Q: What benefits does this transducer offer for professional use?

A: Key advantages include high sensitivity, stable and accurate performance, energy efficiency, corrosion resistance, versatility across multiple applications, and a long operational life. These features together provide consistent results and reduced maintenance for professionals in medical, industrial, and sensing sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free